Inline Viscometers – Our Passion

WELCOME TO MARIMEX

With the ViscoScope® inline viscometer, we have created a modular measuring system,

with which the complex parameter “viscosity” can be monitored easily, reliably and maintenance-free

in almost every industrial application in real time.

Products and solutions: Viscosity sensors and transmitters

ViscoScope® - the premium brand among process viscometers

Industries and Applications

Inline viscosity measurement in almost every industrial application.

Chemical Industry

Our ViscoScope® process viscometer has a modular design that allows us to create the optimum system for practically every application.

- Temperature range from -40 °C to 450 °C

- Pressures up to 550 bar

- Measuring range 0.1 - 2,500,000 mPa.s

- ATEX / IECEx certification

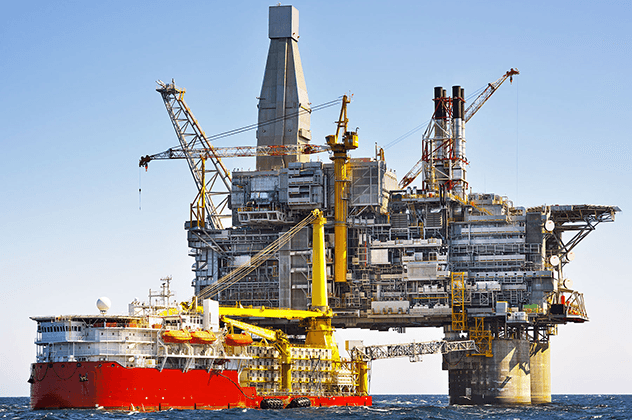

Petrochemical Industry

Whether crude oil is being transported from the Canadian prairies at -20 °C or catalytic cracking is taking place at 500 °C in a refinery, we have the right ViscoScope® process viscometer.

- Oil production at -20 °C

- Temperatures up to 500 °C

- ATEX / IECEx certification

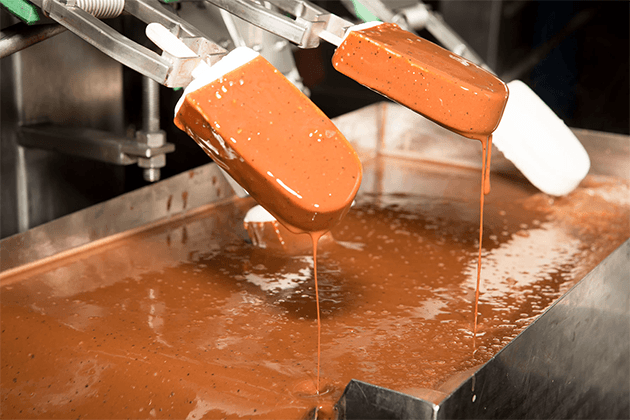

Food Industry

Our ViscoScope® process viscometer cannot measure how good a chocolate tastes, but viscosity is a texture parameter that provides a pleasant mouthfeel.

- Saving raw materials

- pleasant texture

- consistent quality

- EHEDG certificate

Pharmacy & Cosmetics

The ViscoScope® process viscometer supports the user in optimal process management and control. The sensors are EHEDG-certified and equipped with hygienic fittings

- installation without dead space

- hygienic fittings

- Optimisation of the dimensional stability

- Monitoring the final viscosity

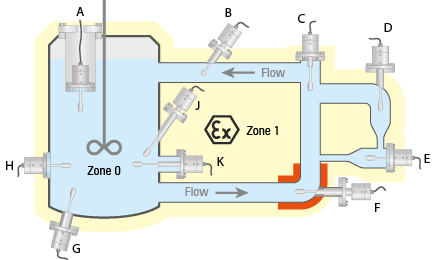

Flexible sensor mounting and installation

Usage of inline viscometers: Project planning support

Benefit from our advantages

Convincing product features

- customized sensor design

- application-specific configuration

- selection of suitable accessories

- Reliable measurement results

- Optimization of industrial processes

Project planning questionnaire

Use our questionnaire for detailed inquiries about our viscometers. With your information, we will advise you individually and prepare a project-related offer without obligation.

Complete questionnaireTypical installation positions

Our ViscoScope viscometer can be installed in any position in vessels, pipes and flow cells. See installation examples here.

See install positionsSupport and Services

We see ourselves not only as a supplier of inline viscometers, but also as a service provider for installations and expert in the interpretation of measurement results.

Our ServicesBenefit from our many years of experience in the Inline viscosity measurement !

Simply contact us by phone or email!