Marimex ViscoScopoe System Design

Best measurement results in almost any industrial application.

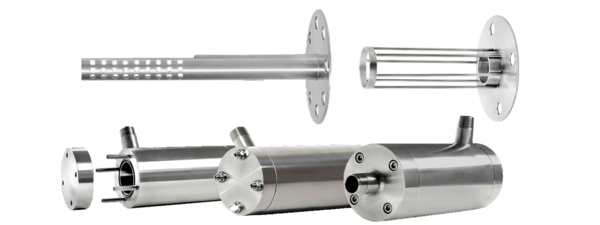

In order to be able to use a process viscometer in applications with small nominal tube and hose sizes, tube expansion is required. Standardized tube expansions reduce flow velocity and increase residence time, which can lead to sump formation and product changes.

Our versatile accessories enable new areas of application for Marimex viscometers:

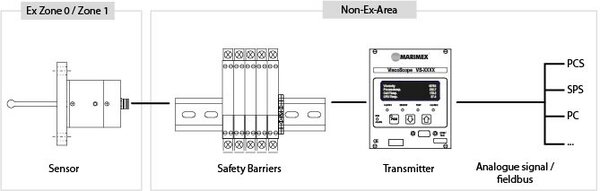

Typical ViscoScope System Design

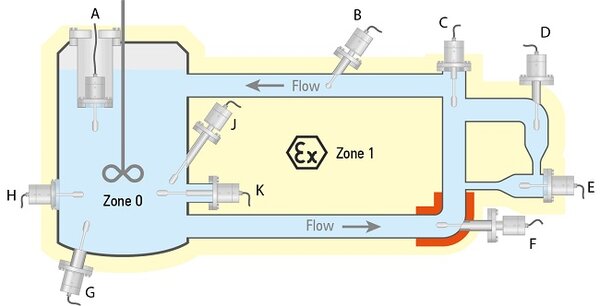

ViscoScope VA-300 Installation positions

Position A: Sensor is attached to the bottom of an immersion tube by means of a flange or thread. The immersion tube is mounted on the vessel cover or the vessel wall.

Position B: Inclined installation in horizontal or vertical pipelines with halfsided flow. The feasibility of this installation depends on the installation dimensions of the sensor, the nominal diameter of the pipeline, the viscosity level and the flow velocity.

Position C: For vertical installation, the installation socket should be kept very short or the sensor should be equipped with a non-active extension to bridge a possible air pocket in the pipe socket. This ensures that the active sensor is completely immersed in the medium.

Position D: The non-active extension bridges and minimises the dead volume in the pipe bend. In addition, the geometry can be adapted to the pipe bend to minimise flow turbulence.

Position E: Installation in flow cell with pipe expansion/reduction. Enables installation even with very small nominal pipe sizes.

Position F: Bridging of a heating jacket by means of a non-active extension. The non-active extension can be adapted to the geometry of the installation spigot / pipe bend to minimise dead volume and flow turbulence. A 2-stage non-active extension allows sealing directly at the gradation near the main pipe.

Position G: When installing in the tank bottom, the installation socket should be kept very short or the sensor should be equipped with a non-active extension to ensure that the active probe protrudes completely from the socket.

Position H: Installation via e.g. block flange or hygienic flange.

Position J: The installation in the inclined installation socket, allows a lower immersion depth of the sensor. The non-active extension bridges and minimises the dead volume in the pipe socket.

Position K: When installing in the horizontal installation spigot, the spigot should be kept very short or the sensor should be equipped with a non-active extension to ensure that the active probe protrudes completely from the spigot.

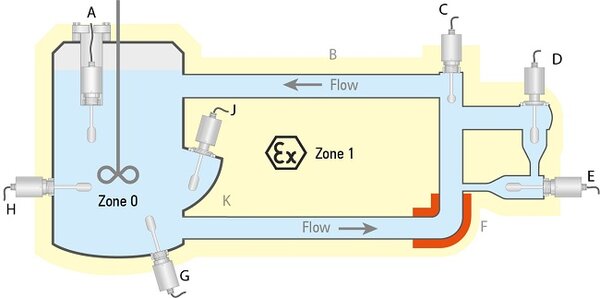

ViscoScope VA-100 installation positions

Position A: Sensor is attached to the bottom of an immersion tube by means of a flange or thread. The immersion tube is mounted on the vessel cover or the vessel wall.

Position B: No installation recommendation.

Position C: For vertical installation, the installation socket should be kept very short to ensure that the active probe is completely immersed in the medium.

Position D: Dead space free installation e.g. in Varivent® corner casing.

Position E: Installation in flow cell with pipe expansion/reduction. Enables installation even with very small nominal pipe sizes.

Position F: No installation recommendation. Position G: When installing in the tank bottom, the installation socket should be kept very short to ensure that the active probe protrudes completely from the socket.

Position H: Installation via e.g. block flange or hygienic flange.

Position J: Installation in „wall pocket“.

Position K: No installation recommendation.

Benefit from our many years of experience in the Inline viscosity measurement !

Simply contact us by phone or email!