Product features and benefits

- maintenance free

- easy handling

- process documentation

- improved quality

- robust, durable sensor

- Optimization in production

Inline Viscosity Sensor VA-100

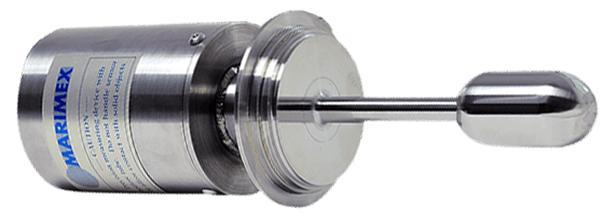

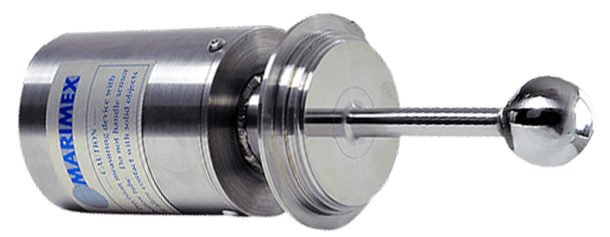

The ViscoScope® sensors are made of high-quality, first-class stainless steel and impress with their intelligent, robust design. All parts in contact with the process are completely welded. Moving parts do not wear out and there are no leaks that damage the inside of the sensor housing. Inside each ViscoScope® viscometer is a Pt100 integrated into the sensor. The VA-100 sensor for viscosity measurement is manufactured as standard and is available with two probe versions in one temperature class and three different process connections.

Images and technical drawings

ViscoScope VA-100 viscosity sensor

- Design: Cylinder

ViscoScope VA-100 viscosity sensor

- Design: Sphere

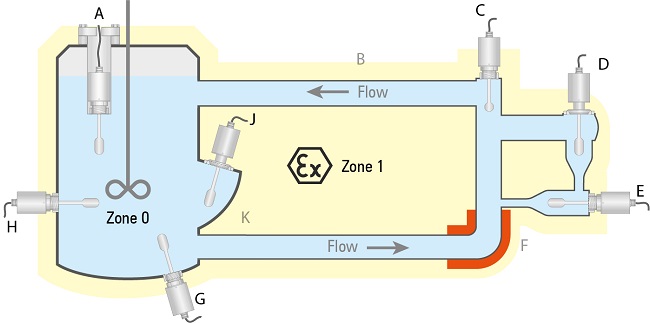

Installation positions

- Install.-position: position-independent

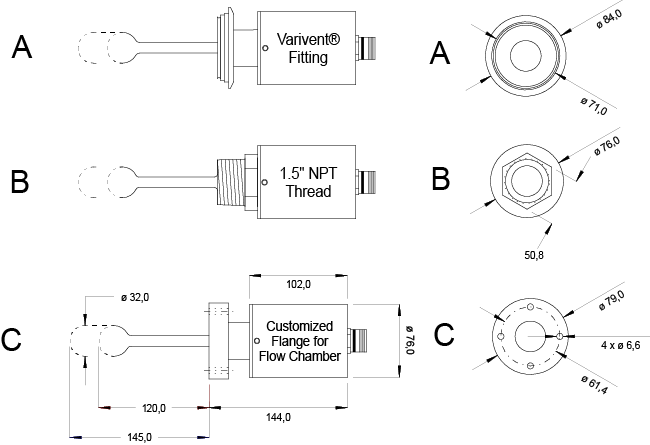

dimensional drawing

Technical data

- Sensor Type

- Cylinder (VA-100C) | Sphere (VA-100B)

- measurement range (in mPa·s x g/cm³)

- 0,1 - 2.500 (VA-100C) | 10 - 25.000 (VA-100B)

- Dimension Sensor

- Ø 32 x 145 mm (VA-100C) | Ø 32 x 120 mm (VA-100B)

- Material

- 1.4571 / 1.4404 (316Ti / 316L)

- protection class

- IP65

- Process Temperature

- from -10°C ... +130°C | (integrated Pt100 in the probe)

- Process pressure

- Vacuum up to 64 bar, depending on fitting

- process connection

- NPT-Gewinde | M48 | Varivent® | Tri-Clamp

- Installation Position

- Reservoir | Tank | Pipeline | Flow cell | Installation is independent of position

- cabel length sensor - transmitter

- Max. 1.000 Meter

- Flow Viscosity

- up to 5m/sec, depending on installation

- Reproducibility

- ± 0.3% or ± 1 digit | ± 0.5% or ± 1 digit

- Ex Certificate

- II 1/2G Ex ia IIC T6...T3 Ga/Gb | (optional)

Fields of Application

- Pastry and bakery products

- Shampoo, shower gels, toothpaste

- Cremes, Lotions

- Gelantine, tinkturen

- Asphalt, bitumen

- Pipeline

- Polymers

- Suspensions, dispersions, emulsions

- Adhesives and sealants

- chocolate, sugar

- Pectin, collagen, gelatin

- Condensed milk, cheese, curd

Documents

ViscoScope VA-100 sensor for inline viscosity measurement

Are you looking for a reliable, maintenance-free inline viscometer to optimize your production process? We have the solution for you! With the ViscoScope® process viscometer you measure the parameters viscosity and temperature in real time.

The inline viscometer is suitable for both continuous and batch processes.

- In continuous processes, the viscosity is permanently monitored. This allows, for example, optimal dosing of solvents in open coating systems, the regulation of the medium temperature for the purpose of maintaining a constant viscosity (adhesive application) or the determination of the molar mass distribution.

- Batch applications are often mixing or reaction processes in which the viscosity curve or the achievement of a defined target viscosity is of decisive importance (homogenization or stopping of a reaction).

The modular process viscometer can be used in virtually all industrial areas, from simple standard installations to extremely individual installation situations. Those who do not have the possibility to connect the transmitter to a process control system and use the process viscometer as a stand-alone system, can record the data with the ViscoView® software. Tube adapters, flow cells, thermowells and immersion tubes as well as protocol and interface converters complete our portfolio.

The high-quality ViscoScope® sensors, made of first-class stainless steel, impress with their intelligent, robust design. All parts in contact with the process are completely welded, so there is no chance of moving parts wearing out or leaks damaging the inside of the sensor housing.

Since temperature also has a significant effect on viscosity, each ViscoScope® viscometer includes a Pt100 integrated into the sensor.

In other words:

Viscosity and temperature are measured simultaneously and at one point. These two parameters are essential for the determination of a temperature-compensated viscosity.

Other special features are the CIP / SIP capability, surface Ra <0.2 µm, dead space free installation or intrinsically safe installation.

The series-produced sensor type VA-100 is available at short notice with two sensor variants in one temperature class and three different process connections. Order-related production of the ViscoScope® VA-300 allows many variants and ensures optimum installation in new and existing plants. With this variety of sensor design variants, modifications to potential installation locations can often be avoided or adapted with little effort.