Viscosity measurement in the cosmetics & pharmaceutical industry

- fermenters

- gelatin, tinctures

- cosmetics

- hollow membranes

- additives (CMC)

Did you know that gelatin solutions with the perfect viscosity are the key to making gelatin capsules that resist being damaged before swallowing? That reaching a defined final viscosity is a practical indicator for the end of an herbal extraction?

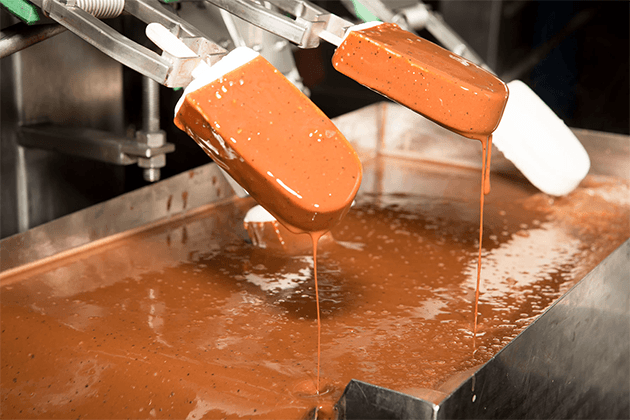

Special requirements also apply in the cosmetics industry. Creams or gels must be kept dimensionally stable in a can or bottle. But they must also spread smoothly and easily on the skin.

Did you know that viscosity is important in gelatine solutions so that the gelatine capsules attain the right firmness and are not damaged before ingestion? That the end of an herbal extraction is indicated by reaching a final viscosity? Special requirements also apply in the cosmetics industry. Creams or gels must be kept dimensionally stable in the can or bottle. But they must also spread well and easily on the skin. With our ViscoScope process viscometer, industrial manufacturing processes in the cosmetics and pharmaceutical industries are optimised.

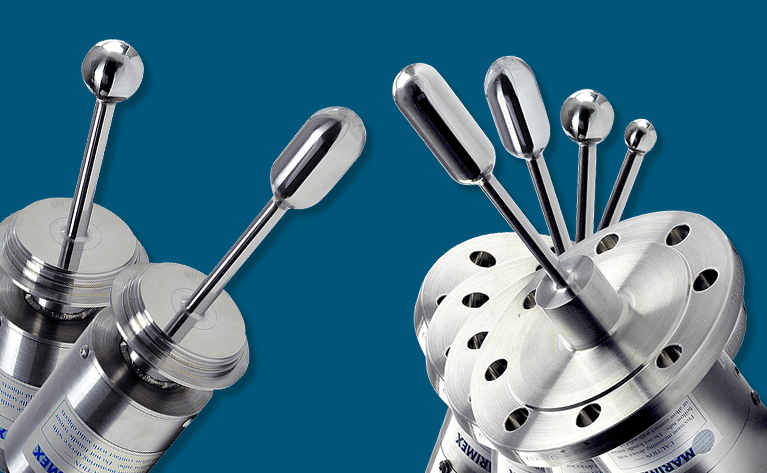

The ViscoScope® process viscometer supports users in achieving optimum process control and monitoring. The sensors are EHEDG-certified and equipped with hygienic fittings for completely dead space free installation.

Applications of Inline Viscosity measurement in the cosmetics and pharmaceutical

Inline viscometer for quality control in the cosmetics manufacturing process

Whether a product is ready for filling or further processing, quality control for personal care products is a major challenge. Inline viscosity measurement allows you to monitor the safety and efficacy of your manufactured product. You can use our measuring instrument to analyse viscosity and thus achieve higher quality in your manufacturing process.

ViscoScope from Marimex supports you as a user in optimal process control. As a result, you can save material costs and energy and deliver a product to your customers with the consistent quality that your customers expect. Through the real-time measurement of viscosity in the process (inline viscosity measurement), you avoid faulty batches and production errors. As a result, you increase your yield and use your resources profitably. Pharmaceutical and cosmetic products have to meet many legal standards and, above all, the requirements of customers in a global competitive environment. Therefore, specific desired properties in terms of fragrance, consistency and usability need to be controlled.

Gain a competitive advantage with inline viscosity measurement by monitoring key process parameters in your manufacturing process in real time. For example, measuring viscosity helps you keep an eye on the chemical stability of your product.

You would like to learn more and contact us? Use our contact form directly or send an e-mail to info@marimex.de. We are looking forward to your inquiry!

Inline viscosity measurement in almost every industrial application.

Recommended Marimex Products

Marimex® Viskositätssensor ViscoScope

Inline Viscosimeter

The ViscoScope® Process Viscometer VA-100 is a maintenance-free precision viscometer for reliable real-time measurement of the dynamic viscosity of liquids.

Read moreMarimex® Transmitter

ViscoScope® Transmitter

The VS-D250 and VS-4450 transmitters are compatible with all ViscoScope® VA-100 and VA-300 sensors and their predecessors. This ensures the highest possible flexibility for optimal instrument selection and replacement of older transmitters.

Read moreIndustries and Applications

Inline viscosity measurement in almost every industrial application.

Benefit from our many years of experience in the Inline viscosity measurement !

Simply contact us by phone or email!